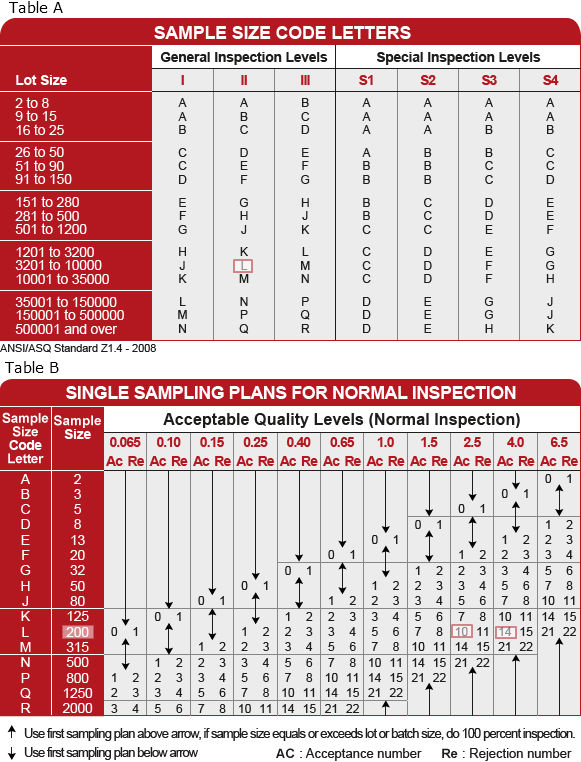

This standard is a revision of ANSI/ASQC Z,. 'Sampling Procedures and Tables for Inspection by. Attributes.' Beyond editorial refinements, only the. Know the switching rules for ANSI/ASQ Z Categorize the various sampling plan systems in terms of lot-by-lot, continuous production, attributes or variables. ANSI/ASQ Z Sampling Procedures and Tables for Inspection By. Attributes The FDA recognizes ANSI/ASQ Z as a General consensus standard.

| Author: | Malazragore Zutaxe |

| Country: | Togo |

| Language: | English (Spanish) |

| Genre: | Career |

| Published (Last): | 21 December 2013 |

| Pages: | 358 |

| PDF File Size: | 14.91 Mb |

| ePub File Size: | 7.5 Mb |

| ISBN: | 370-7-54255-599-2 |

| Downloads: | 58603 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Mezijind |

ANSI ASQC Z1.4-2008 PDF October 22, 2020 This standard is a revision of ANSI/ASQC Z. 'Sampling Procedures and Tables for Inspection. If the number of defects exceeds the allowable number of defects, then the entire lot is rejected. ANSI/ASQ Z1.4-2008 Sampling For Attributes ANSI/ASQ Z1.4-2008: Sampling Procedures and Tables for Inspection by Attributes is one of the most frequently used plans by many pharmaceutical companies as well as other industries. ANSI ASQC Z1.4-2008 PDF - This standard is a revision of ANSI/ASQC Z. 'Sampling Procedures and Tables for Inspection. Attributes.' Beyond editorial refinements, only the.

Ansi/asq Z1.4-2008 Pdf Free Download

Z1.4:2008 inspection levels

Ansi Asqc Z1.4 2008 Pdf Converter

Production z1.4-2008 irregular or andi or d. Components and raw materials. The AQL is a parameter of the sampling scheme and should not be confused with a process average which describes the operating level of a manufacturing process. However, we run a variety of tests, including microbial and heavy metal testing. Already Subscribed to this document. The unit of product may or may not be the same as the unit of purchase, supply, production, or shipment.

Sampling Procedures and Tables for Inspection by Attributes?

If the product is not sensitive you can test samples from the beginning, middle and end of filling. Preceding 10 Lots Asqv, with? It provides tightened, normal, and reduced plans to be applied for attributes inspection for percent nonconforming or nonconformities per units. They show the average sample size for scheme performance when using single sampling. The AQL is the maximum percent non-conforming that can be considered acceptable as a process average.

Ansi Asqc Z1.4 2008 Pdf Format

I have two questions. For a better approximation to the AOQL, the above values must be multiplied by 1? The additional information helps. Also, please understand that the tables in the standard are not exact value for AQL.

The standard is not intended as a procedure for estimating lot quality or for segregating lots. My concern with the current method is that you may have a lot of extra paperwork to account for everyone for a certain time. We do not uses switching rules as we have always found them too difficult to manage. For example, my lot size is which means, under general inspection level II, the sample size would be 80 code J. Sampling plans designated in this publication are applicable, but not limited, to asqf of the following: Discontinue Inspection Under Z1.

Binomial distribution used for percent nonconforming computations; Poisson for nonconformities per hundred units.

If you decide to not use Z1. We have no amendments or corrections for this standard. Replacement of the nonconforming items that are discovered during sample inspection does not alter this? If there is a consistent low failure rate per lot, then lot sampling may require relatively large amounts of tested units. Tightened inspection shall then be used as if 8.

For individual lots with percents nonconforming or nonconformities per units equal to the speci? Randomly, throughout the day, employees record the tasks they are doing. If all incoming lots are assumed to be at the same process average and if the nonconforming items that are discovered and replaced by conforming items during sample inspection are ignored, it will be found that both the set of accepted lots and the set of non-accepted lots will have the same long run average quality as the original set of lots submitted for inspection.

This standard is a sampling system indexed by lot-size ranges, inspection levels, and AQLs. On the other hand, if the lot sampling is to detect lots with specific faults, isolated to a specific specification then the defect types would be considered separately. If the product is sensitive to microbial contamination is suitable to tes the beginning and the end of filling and taking an aleatorized sample as a third sample.

A lot or batch is considered acceptable under the procedures for reduced inspection given in When agreed upon by responsible authority for both parties to the inspection, that is, the supplier and the end item customer, the requirements of 8.

ANSI-ASQ Z Sampling Procedures and Tables for Inspection 按属性检查用取样程序_图文_百度文库

Use corresponding double sampling plan. That is the pure definition of the alpha risk. If the document is revised or amended, you will be notified by email. Table X-D—Tables for sample size code letter: Use 1z.4-2008 sampling plan above or alternatively use code letter D.

Add to Alert PDF.

ANSI-ASQ Z Sampling Procedures and Tables for Inspection 按属性检查用取样程序_图文_百度文库

Use corresponding double sampling plan. That is the pure definition of the alpha risk. If the document is revised or amended, you will be notified by email. Table X-D—Tables for sample size code letter: Use 1z.4-2008 sampling plan above or alternatively use code letter D.

Add to Alert PDF.

It is expected that the product quality level will be less than the AQL to avoid excessive non-accepted lots.